Have you spent hours debating how to properly rate the failures in your Design FMEAs only to realize that the calculated Risk Priority Numbers (RPN) are suggesting you address issues that you know aren’t the ones you should be working on? I thought so…

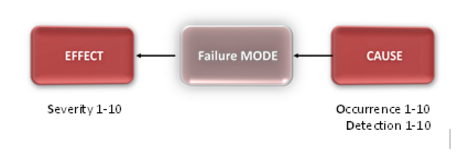

One of the most fundamentally important aspects of the FMEA is the rating process for the failure effects (Severity) and the failure causes (Occurrence & Detection). We need to challenge its effectiveness and make it better.

The Design FMEA is a subjective assessment of the adequacy of the product design specifications in defining a product capable of meeting the product design requirements. In other words, you are assessing how effectively the design outputs meet the design input requirements… or the risk of not meeting them.

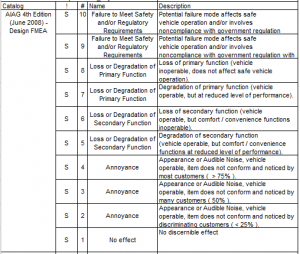

The rating table guidelines we have been expected to use are found in the Potential Failure Mode and Effects Analysis (FMEA) Reference Manuals offered by AIAG, VDA, and SAE. Some modifications can and should be made to these tables to increase their effectiveness. For those of you reading this who may be concerned that they may not be compliant with QS9000 or TS16949 guidelines if they make changes to the tables, the AIAG Potential Failure Mode and Effects Analysis (FMEA) Reference Manual gives permission for the changes. The manual states, “Suggested Evaluation Criteria: The team should agree on an evaluation criteria and ranking system that is consistent, even if modified for individual product analysis.” Also, note that AIAG, VDA, and SAE offer “guidelines” for the FMEA, not “rules” as many believe.

The rating table guidelines we have been expected to use are found in the Potential Failure Mode and Effects Analysis (FMEA) Reference Manuals offered by AIAG, VDA, and SAE. Some modifications can and should be made to these tables to increase their effectiveness. For those of you reading this who may be concerned that they may not be compliant with QS9000 or TS16949 guidelines if they make changes to the tables, the AIAG Potential Failure Mode and Effects Analysis (FMEA) Reference Manual gives permission for the changes. The manual states, “Suggested Evaluation Criteria: The team should agree on an evaluation criteria and ranking system that is consistent, even if modified for individual product analysis.” Also, note that AIAG, VDA, and SAE offer “guidelines” for the FMEA, not “rules” as many believe.

Let’s consider the rating categories:

Establishing the Design FMEA Severity Rating

The first rating we’ll consider is the severity rating where we assign an ordinal value between 1-10 based on a table of definitions. The criteria of these ratings consider the impact of the failure with regard to Safety, Government Regulations, Loss/Degradation of Primary Function, Loss/Degradation of Secondary Function, and Annoyance to the end user.

Establishing the Design FMEA Occurrence Rating

The second rating that must be determined is the occurrence rating. Unfortunately, another ordinal value between 1-10. The occurrence rating in the Design FMEA corresponds to the probability that the failure mode will occur due to the cause. There is a lot of ambiguity here, especially if we are considering a new or modified design which may also be coupled with more stringent (or unknown) use-case requirements. We need to consider design experience with regards to the maturity of our design rules and guidelines, and the experience of our engineers in designing such products.

Establishing the Design FMEA Detection Rating

The third rating that must be determined is the detection rating. The detection rating is used to define the effectiveness of the Design Controls (i.e., testing) in assessing the probability that the failure mode will occur due to the failure cause to which it is linked. What’s usually lacking here is that we might think our tests are certain to detect issues in the design. But what if we only provide the test with “nominal” condition parts? Are we prepared for the fact that when we actually build our parts under standard manufacturing process variation that we might assemble combinations that are less capable? Can the testing detect scenarios it isn’t presented with? If this isn’t rolled into our Detection rating, we’re not truly understanding the risk.

What do we do about this? We have to ensure that our rating catalogues (i.e., the definitions) are good enough for our teams to apply the ratings correctly and consistently – the same way each time and the same way no matter which team member is assessing. Now, where have we heard about this before? You’ve likely heard of the “Gage R&R”, which assesses the Repeatability and Reproducibility of a measuring device while being put to use by multiple operators. Well, there exists a similar analysis for us called the “Attribute Gage R&R”, which can tell us if we have a statistically sound assessment criteria in our rating catalogue “gage”.

Some readers may now be asking themselves about the impact of the above severity rating setting methodology on Risk Priority Number (RPN) ratings. If you are concerned, don’t worry. Although RPN is identified by most FMEA manuals as the method to be used to determine the issues you should be working on, if you use RPN as your main tool for prioritization, you risk being wrong as often as 50% of the time. A better way for prioritizing issues to be worked on in the Design FMEA is through the use of the Risk Matrices. But that’s another time. Carry on!